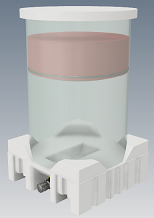

Piston Tanks

For Bulk Grease Applications

1. Reduced Waste - leaves approximately 6 liters of

grease in a 1,500 liter tank.

Drums tend to

leave allot of grease in the bottom of the drum that has to be

disposed of or transferred to another drum.

Sloped bottom tanks rely on the weight of the grease to flow the

grease to the bottom of the tank and inlet of the grease

pump. As the grease gets lighter, it is not uncommon to leave 25% of

the grease in the tote tank.

1. Reduced Handling & Shipping Costs - as compared to the storage and handling of drums

or sloped bottom tanks.

2. Improved Productivity -

Reduced down time waitng on drum changes and resetting of the pumping equipment.

Pumps and pipelines can be used to deliver grease from

the bulk tank to several application points.

3. No drum disposal costs

4. Safey - reduction in handling operations reduces the risk of personal injury.

5. Reduced risk of Product Contamination